To ensure total satisfaction for each of our customers, dti EXACT™ goes above and beyond standard quality norms. Every member of the team is involved in quality control and each principle and program in place facilitates our ability to prevent defects and ensure all customer requirements are met.

Quality Assurance at dti Exact™

QUALITY PRINCIPLES

- Fully identify and understand the requirements of our customers.

- Create effective production strategies that encompass each customer requirement.

- Fabricate each product within controlled environments with proficient personnel and processes.

- Verify and measure those products against each customer’s requirements.

- Consistently review, evaluate and improve areas of the production strategy contributing to product quality and customer satisfaction.

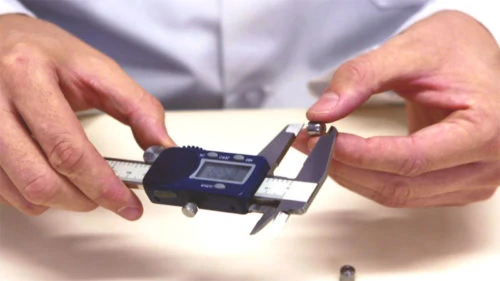

EQUIPMENT

- Nikon CNC Comparator

- Laser Interferometry

- Multi-Point Inspection

- Scanning Electron Microscope

Quality Assurance

dtiEXACT provides machining services that produce reliable, high-precision parts and components. Our rigorous quality assurance process guarantees customer satisfaction with every product.

The quality assurance process begins before we even submit a quote, with a review of the customer’s specifications. Our team creates a machining plan to make sure the manufacturing process runs smoothly. After production, every machined part is inspected for accuracy and measured against the customer’s requirements. Our team is committed to quality and ensures that each customer receives exceptional products that meet their demands.

Quality Assurance in Machining Services

Quality assurance is critical in any machining service, as manufacturers must ensure the parts and components produced will meet the customer’s requirements. Our quality assurance process guarantees that any problems are identified and corrected quickly. dtiEXACT quality control and inspection takes place at multiple steps in the machining process with final thorough inspection of each part or component at completion before leaving the facility, ensuring total confidence in our products.

Quality control procedures at dtiEXACT

- Review customer’s specifications: First steps are to review the customer’s part specifications for compatibility with our production equipment and ensure ample time on our production schedule to meet delivery requirements. Next, the group takes into consideration material availability, part tolerances, special tools/tooling which may be needed, programming resources, and confirmation that our expertise aligns with the opportunity. Proper planning is integral to achieve the final quality outcome of every customer order.

- Create a machining plan that meets or exceeds the customers specifications: dtiEXACT’s experienced team members collaborate with each customer to create an optimal machining plan. Every machined part is then produced according to this plan to ensure consistency, quality, and on-time-delivery.

- Final inspection before leaving the facility: dtiEXACT’s rigorous quality assurance procedures include final inspection as measured against the customer’s requirements for accuracy before the finished products leave the facility.

- Commitment to quality: At dtiEXACT, customer satisfaction is paramount, which is why we are consistently evaluating and improving our production and inspection strategies. This commitment to quality from every member of our team is what sets us apart from the competition.

Quality Principles

These guidelines guarantee that our customers will receive goods that exceed their expectations and that machined parts will be precise and of the highest caliber

- Fully identify and understand the requirements of our customers: We accomplish this by working in collaboration with each customer, ensuring that all specifications are met and that each part is examined for accuracy and quality before leaving the facility. Our dedication to quality ensures that you will receive a product you will be pleased with.

- Create effective production strategies that encompass each customer requirement: dtiEXACT makes sure that all requirements are met by implementing effective production strategies that are tailored to each project. We manufacture all machined parts to the most outstanding possible standards. Because of this attention to detail, you may be confident that you will receive a product that fulfills your expectations.

- Fabricate each product within controlled environments with proficient personnel and processes: dtiEXACT’s machining services are carried out in a regulated setting with skilled workers and equipment. Working in a controlled environment ensures that each product is manufactured to the highest standards possible and that you can be confident in the quality of the product you receive.

- Verify and measure those products against each customer’s requirements: After production, we review the customer’s requirements to verify that each product adheres to the predefined specifications.

- Consistently review, evaluate, and improve areas of the production strategy contributing to product quality and customer satisfaction: The team regularly reviews customer specifications, machining plans, and the production process to ensure that each product meets or exceeds customer expectations for accuracy and quality. This commitment to quality means that you can be confident in the products you receive.