Machining Services

Searching for precision machining services? Choose dti EXACT™ as your manufacturing partner.

Machining services are essential for creating metal parts and components with a high degree of precision. The machining process involves using tools to remove material from a workpiece to create the desired shape or finish. CNC Machining can be performed using various methods, such as Swiss machining, vertical milling, and CNC turning. Each method is specialized to machine different sized parts and different part features, so choosing the right machining method for your project is essential.

dtiEXACT offers a wide range of machining services that can be custom-tailored to your specific needs. We have state-of-the-art equipment and a highly skilled workforce that can handle even the most complex machining projects.

We can meet your requirements whether you need a single part or a large production run. We also offer value-added services, such as assembly and packaging, to save you time and money. So if you’re looking for a machining partner that can provide quality parts at a competitive price, contact dti EXACT today.

Machining Capabilities

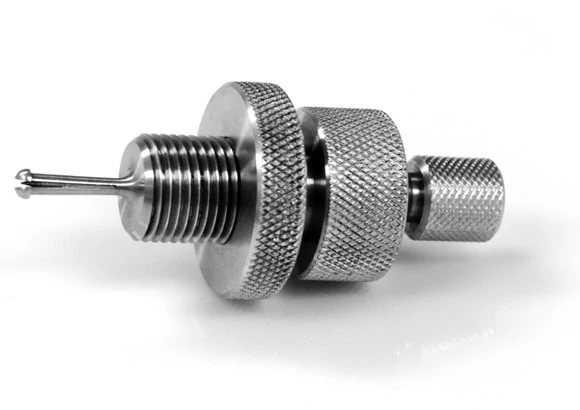

Swiss Machining

Swiss machining is a type of lathe-based machining that is used to create small, precise parts. It offers many advantages over other methods, including increased speed and precision, less setup time, and the ability to create complex geometries.

This type of machining is exact and can produce parts with tight tolerances of ±0.0001″. In addition, Swiss machining is high-speed and efficient, which makes it an excellent option for high-volume production runs.

Our team of experienced machinists specializes in Swiss machining, and we use that knowledge to produce high-quality parts for our clients. Contact us today for more information on our precision machining services.

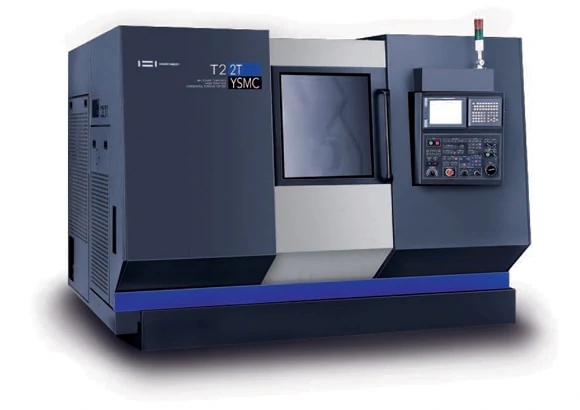

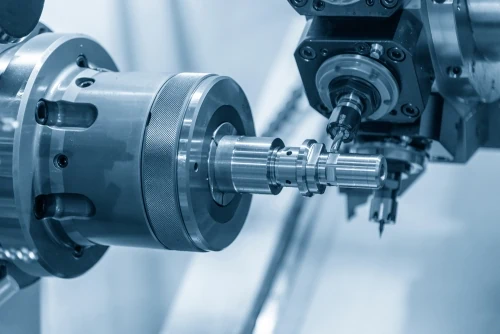

CNC Turning

CNC Turning

CNC Turning is a highly advantageous machining process that allows us to create both precision parts and simple components. We leverage industry-leading technology to increase production and manufacture parts more cost-effectively.

CNC turning is generally used to produce cylindrical parts but can also be used to create complex shapes. Our CNC turning capabilities help us produce parts with very tight tolerances quickly and efficiently. We can machine parts up to 8″ in diameter and 20″ in length with a tolerance as tight as ±0.0001″.

If you need CNC turning services and precision machining, contact the experts at dtiEXACT. Our helpful team will ensure that your final product meets all requirements.

Vertical Milling

Vertical Milling

Our CNC vertical milling machines produce precision machined parts in both prototype and production run quantities. The vertical milling machine can manufacture parts up to 40″+ in length, 26″ in width, and 25″ in height. This process is perfect for customers who desire a close tolerance, as we can achieve critical tolerances as tight as ±0.0005″.

This process is ideal for machining common materials like steel, aluminum, and plastics. Vertical milling also allows us to machine a range of exotic alloys, such as precipitation hardened steels and aluminum-nickel-bronze.

In addition to our machining capabilities, we also provide complete finishing and assembly services. These include lapping, brazing, adhesive bonding, and mechanical assembly. Contact us for more information on our CNC vertical milling services.

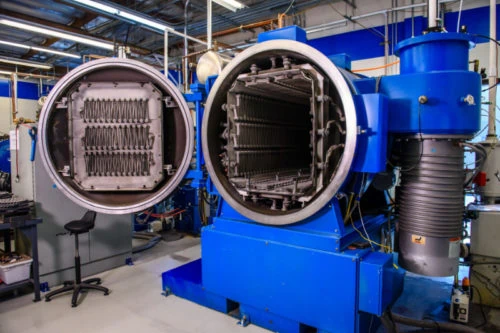

High Vacuum Brazing

High Vacuum Brazing

High vacuum brazing is a process that joins parts together using heat to melt a bonding agent within an atmosphere controlled vacuum. The process is often used to join dissimilar metals or to create a seal between two pieces of metal. High vacuum brazing is typically performed using an inert gas in a vacuum chamber. Inert gas, such as argon, helium or nitrogen, are often times used to backfill during the cool down process.

Vacuum brazing is performed in an evacuated chamber free of all air. This creates a high vacuum environment that prevents oxidation of the joint. High vacuum brazing is often used for applications where a hermetic seal is required.

We can braze various materials, including stainless steel, carbide, ceramic and diamond. Our high vacuum brazing services are perfect for creating hermetic seals in medical devices, aerospace components, and semiconductor components. Contact our machining specialists today if you need high vacuum brazing services.

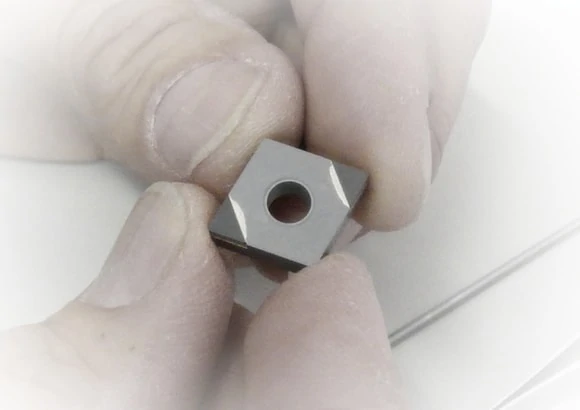

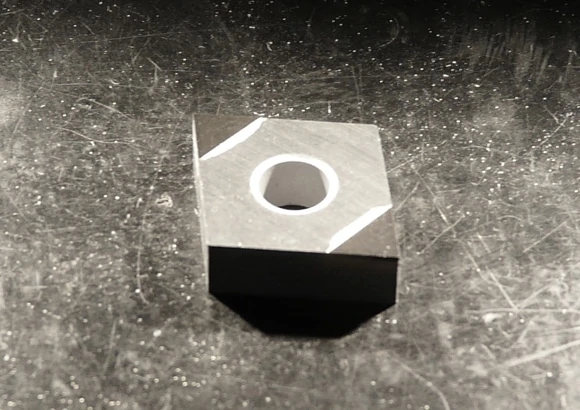

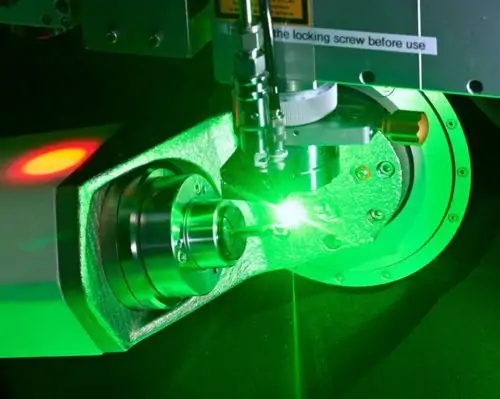

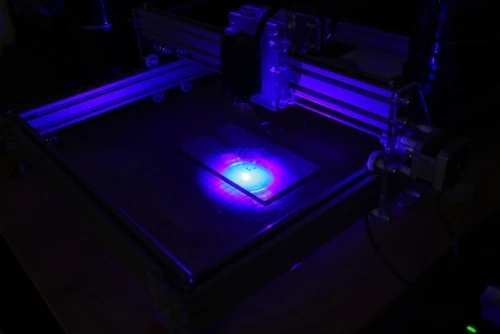

Diamond Laser Cutting, Shaping & Drilling

Diamond Laser Cutting, Shaping & Drilling

At dtiExact, we offer laser cutting and drilling services to produce high-precision diamond orifices for waterjet cutting. We can cut various diamonds, including natural, lab grown, PCD, CVD, and MCD diamonds. Our machines can cut diamonds with precision holes as tight as 0.002″, with a part length and width up to 6”. Our laser cutting and drilling capabilities allow us to produce accurate, reliable diamond parts with a short turnaround time.

We also provide contract laser cutting and drilling services, so both small and large manufacturers can take advantage of our industry-leading diamond manufacturing technologies. Request a quote today to learn more about our laser cutting and drilling services.

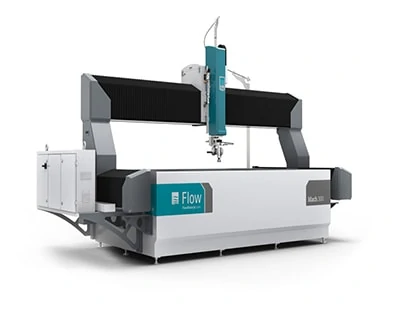

Waterjet Cutting

Waterjet Cutting

Waterjet cutting is a machining process that uses high-pressure water to cut materials. This process can be used on various materials, including metal, glass, stone, and composites.

Waterjet cutting offers several advantages over other machining methods, such as plasma and laser. First, waterjet cutting produces a minimal heat-affected zone (HAZ), which means that the material being cut can retain its structural integrity and properties. Another advantage of waterjet cutting is versatility — abrasive waterjets can cut material from 1/16 inch to over 10 inches thick.

Finally, our cutting machines can cut parts as large as 5’x10’ and thickness up to 8”, with varying cut quality to match your finish requirements and budget. dti EXACT is proud to offer waterjet cutting as one of our many machining services.

Value Added Services

Value Added Services

At dti EXACT, we pride ourselves on being a one-stop shop for all your machining needs. In addition to our world-class machining capabilities, we offer a range of value-added services that can save you time and money.

- Laser marking is a permanent, tamper-proof way to identify your parts and products. We can laser mark logos, serial numbers, barcodes, and just about any other text or image onto your parts. This is an ideal solution for customers that need marking services for their precision parts.

- Kitting services ensure that all the components you need for assembly are shipped together, a convenience for customers that want their various parts packaged as a single unit.

- Custom packaging allows us to tailor our packages to meet customers’ specific needs.

- Assembly services mean we can take care of the entire assembly process for you, from start to finish. Whether you need a few parts assembled or an entire product line, we have the experience and expertise to get the job done right.

dti EXACT™ has the right tool for the job

dti EXACT is a full-service machine shop that can take your project from start to finish. We offer Swiss machining, CNC turning, vertical milling, and a range of other metal fabrication services. With over 30 years of experience in the industry, we have the expertise and equipment to produce high-precision parts. Plus, our team is dedicated to providing superior customer service every step of the way.

Contact us today to learn more about how we can help you achieve your manufacturing goals!

QUALITY ASSURANCE

To ensure total satisfaction for each of our customers, dti EXACT™ goes above and beyond standard quality norms. Every member of the team is involved in quality control and each principle and program in place facilitates our ability to prevent defects and ensure all customer requirements are met.

QUALITY PRINCIPLES

- Fully identify and understand the requirements of our customers.

- Create effective production strategies that encompass each customer requirement.

- Fabricate each product within controlled environments with proficient personnel and processes.

- Verify and measure those products against each customer’s requirements.

- Consistently review, evaluate, and improve areas of the production strategy contributing to product quality and customer satisfaction.

EQUIPMENT

- Nikon CNC Comparator

- Laser Interferometry

- Multi-Point Inspection

- Scanning Electron Microscope

MANUFACTURING SUPPORT

dti EXACT™ employs top of the line delivery systems, project support, and engineering expertise to provide total

manufacturing solutions. Delivering the full spectrum of reliability and service ensures our customers receive the best support from initial inquiry to finished goods received.

DELIVERY SYSTEMS

dti EXACT™ strives for a standard 2-week lead time on standard parts and works with you to determine the best delivery systems to fit your needs.

- Custom delivery programs

- Kanban delivery

- JIT systems

- Supply chain management

PROJECT SUPPORT

- Project management team for planning, coordination and solution optimization

- Project scheduling

- Requirement documentation management

- Communication throughout the entire process

- Solution generation and problem solving

- CAD/CAM support (SolidWorks, Camworks)

- Drafting and file conversion (STEP, IGES, DXF, PDF)