Common Machining Processes and Materials

Leave a CommentMany parts and products can be produced through machining processes. However, it is important to select the process(es) utilized for production carefully to ensure your machined components fully meet the requirements and restrictions of your application. Given the wide range of machining options available, it can be difficult to choose the right one(s), but an experienced manufacturing partner—such as dti EXACT™—can help you navigate the selection process.

At dti EXACT, we offer contract machining and manufacturing services. Armed with vast experience and top-of-the-line equipment, we have what it takes to deliver quality solutions for all small, complex, and precision component needs. Our expert team can help you evaluate your specifications and identify which machining process(es) you will need to turn your idea into reality. Below, we’ve highlighted some of the most common machining processes and outlined key considerations to keep in mind when vetting your options to serve as a helpful machining process and material selection guide.

Common Machining Processes

Machining is a broad term encompassing manufacturing processes that turn a workpiece into the desired component by removing material. Some of the most commonly used are:

Swiss Machining

Swiss machining is a machining process generally used to create small, complex, and precise components in high volumes. Compared to traditional lathe processes, it offers tighter part tolerances, faster tooling changes, a lower chance of part deflection, and a smaller need for secondary processing, all of which can lead to increased productivity and profitability for the manufacturer.

This machining process can accommodate a variety of metal and non-metal materials. Examples include aluminum, brass, copper, stainless steel, steel, and plastic. When selecting a material for Swiss machining operations, it is vital to consider how different factors will affect the overall project, including with regard to machining speed, retooling frequency, and production cost.

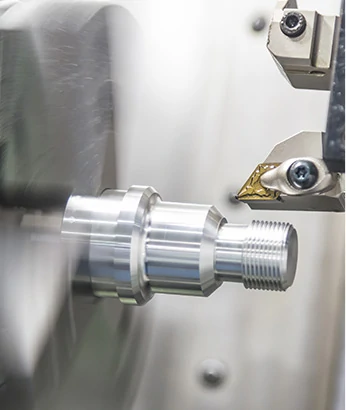

CNC Turning

Computer numerical control (CNC) turning is a machining process that utilizes a combination of software and hardware to control the motions and actions of machine tools and workpieces. The stationary machine tool(s) remove(s) excess material from a rotating workpiece to create the desired component. Compared to manual turning methods, it offers better precision, faster speeds, higher efficiency, and safer operator conditions, resulting in high-quality components that are made cost-effectively and time-effectively.

This machining process can be used for various metal and non-metal materials. Examples include alloy steel, aluminum, brass, bronze, carbon steel, copper, stainless steel, titanium, UHMW, and other plastics.

Vertical Milling

Vertical milling is the most common milling method. It uses milling machines with vertically oriented spindles to hold and rotate the cutting tool(s) against the stationary workpiece to remove excess material. It offers a number of advantages over horizontal milling, including greater visibility during operations, easier use requirements, and lower equipment costs.

Laser Cutting & Drilling

Laser cutting and drilling are manufacturing processes that utilize high-powered lasers to form cuts and holes on a workpiece. Compared to conventional cutting and drilling processes, they offer greater accuracy and precision, shorter lead times, and broader design freedom.

These processes are excellent for thin or thick materials. They can easily create cuts or holes in metals and other materials that would be difficult to process using other methods, such as diamonds.

Waterjet Cutting

Waterjet Cutting

Waterjet cutting is a manufacturing process that uses high-pressure waterjets to cut a workpiece into the desired shape and size. It offers a variety of advantages over other cutting processes, such as better edge quality, higher cutting accuracy, and lower risk of thermal distortion.

This manufacturing process can be utilized for a range of materials, including metals, plastics, wood, and stone. It is highly effective at cutting hard or thick workpieces that would be too difficult for other methods, such as heat treated alloy steel.

Selection Considerations for Machining Processes

While all machining processes produce components by removing excess material from the workpiece, each has distinct benefits and limitations that make it suitable for different manufacturing projects. The trick to choose the right process(es) for a project is evaluating all of these benefits and limitations and selecting the machining method(s) that best suit(s) your needs. Some of the factors to consider when evaluating your options include:

- Complexity: The machining process(es) you choose should be able to accommodate your component design, whether it is simple or complex.

- Tolerances: The machining process(es) you choose should be able to produce your components to your specifications, including with regard to tolerances.

- Timeframes: The machining process(es) you choose should be able to generate the parts/products you need in the volumes you need within the timeframe you need them.

- Budget: The two main costs associated with manufacturing projects are tooling cost and part cost. It is important you choose a machining process whose cost of tooling and part production fit within your project budget.

- Material: The machining process(es) you choose should be able to handle the materials you select, whether they are hard or soft and thick or thin. At dti EXACT, we can machine various materials, including aluminum, brass, bronze, copper, carbon steel, stainless steel, tool steel, specialty alloys, plastics, and diamond. We can work with you to find the best material for your project.

Contact the Machining Experts at dti EXACT Today

Selecting the right machining process and material can be challenging. Fortunately, the machining experts at dti EXACT are here to help. As an experienced contract machining and manufacturing service provider, we have the knowledge and skills needed to help customers in virtually any industry devise a solution that meets their tight tolerances, high standards, and short timelines. You can trust us to make your next precision machining project a success.

If you have any additional questions or concerns about machining processes and materials, contact us today. We would be happy to answer or address them. Request a quote to discuss your project specifications with one of our representatives.

Waterjet Cutting

Waterjet Cutting